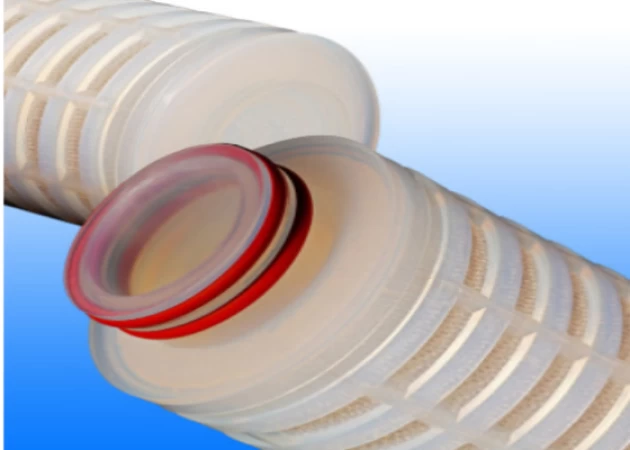

The fluid gets poured through a type of porous medium, depending on the size of the solid particles inside the fluid. The pore sizes vary to ensure that all unnecessary particles in the fluid are out. This procedure is known as filtration. However, you need to know more about filter ratings when you order membrane filter cartridges.

The filtration procedure is essential in the workflow of some types of industries which order membrane filter cartridges. The aim is to remove impurities from a substance so that it can be usable. Some technologies facilitate the removal of these impurities, for example, water contaminated with crude oil is purifiable and gases too. The objective of the filtering process is to separate impure substances from gases and liquids for them to be suitable for various purposes including industrial and commercial.

Industries worldwide depend on purification as a necessity for future development, research, and work standard. The factors to consider when choosing a filtering medium for filtration include:

The pore-size

Chemical compatibility

The type of liquid that is going to get filtered through it

A filter rating usually means the ability of a medium to separate impurities like particles of various sizes ranging from tiny to the biggest on a stated measurement. A filter shows the output or performance that is a direct proportion of the filter rating. Besides, the rate relies on:

The effectiveness of the suspension

The volume of the remaining particles collected

The amount of utilised energy recorded when filtration was going on

The cost of filter usage

A low rate of filtration makes the pressure drop significantly; hence the operations cost increases. On the other hand, a high percentage of filtration rises pressure, thus, it becomes cheaper. A way of making sure that the filtration rate remains constant is rinsing the sieve to get rid of the solid debris which sticks on the surface through a process called reverse flow.

The significance of the purification process is equal to that of filter ratings. It is crucial to maintain a standard rate of filtration by cleaning the sieve efficiently until the process reaches competition. The choice of a sieve when purifying contaminated substances should be in a wise manner by considering all the factors and features available in the filters for the result to be a success.

The Definition of a Filter

It is a sieving material that prevents solid particles from passing through when a contaminated liquid goes through it. The pores should be smaller to ensure that the filter catches all solid matter during the purification process.

The Procedure of Purification

Various industries globally depend on filters to clean up the ingredients of specific processes of their liquid products. The states of matter than can be purified are liquids and gases through technological procedures. The air in its natural form contains some impurities that can change the desired result. Also, fluids need filtering to remove any unwanted substances for human consumption and industrial use. For example, water comes from rivers, and then it is tapped into a purification plant that cleans and decontaminates the water into pure water, which gets distributed through pipes for residential and commercial purposes.

A good filter ensures proper filtration. It needs to be a specific character, i.e., the features include the size of the pores, the reaction of the sieve with chemicals, and the rating of the filter media. It is essential to be keen when choosing the right filter for a specific fluid for the best result to be achievable.

Details About Filter Ratings

It involves measuring how good a filter is by looking at the amount of impure matter sieved. A precise filtration rate means excellent performance. The rating will only be a high one if the suspension is efficient, the volume of impurities sieved is unquestionable, the energy used up is low, and operation costs are cheap due to less energy usage.

There are ways to ensure that the filtration rate stands at a high level. They include thorough cleaning of the filter media to wash away the impurities that get clogged inside it through a reverse flow process, using a stainless media that increases the filter rating and enhances the cleanability of the equipment.

Filter rating is significant, just like filtration in the purification process. It is vital to keep the media always clean and protect it from damage so that it can maintain the level of rating desired. The filtration process will succeed if those measures get utilised during every task that requires the use of a filter. The correct filter choice depends on the type of impure substances and the features of the variety of sieves.