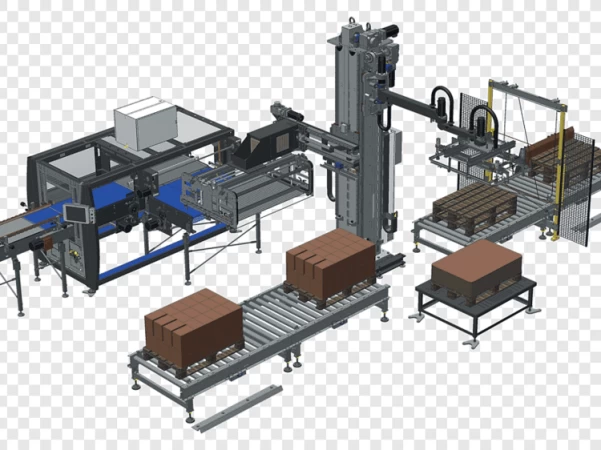

As time passes, men invent cranes of different sizes to move and pull the gigantic stuff from one place to another, and now, it’s the more advanced form is palletizer. A palletizer is an automatic system, that picks goods on or of load carriers, such as pallets. A palletizer is connected to a gantry robotic or palletizing robot and both handles individual products, product rows or full product layers. Columbia Machine manufactures high level, ground level and robotic palletizers; load transfer stations and provides complete system integration. All tools is built with the very best priority on security, flexibility, efficiency and help to make sure your palletizer maximizes manufacturing every day for the lifetime of your palletizer.

Of the two forms of automated palletizers, an inline palletizer is generally faster and works well with high volumes of a single type of goods, such as canned goods. However, an inline palletizer doesn’t work as well for manufacturers producing many different types of items at the similar location. For occasion, an inline palletizer may have a robotic arm next to it to take over when atypical products are being palletized.

Today, a programmed low-level palletizer, otherwise called a story level palletizer offers a wide assortment of delivery arrangements, including dependability, adaptability, expanded efficiency, and a little device impression. With a low-level palletizer, the bed stays at floor level or near floor level all through the stacking procedure. Low-level palletizers can give an assortment of advantages to industrial facilities just as increments in productivity for stacking beds and moving them starting with one spot then onto the next. It will also work efficiently and accurately with same manner.

Today, we are going to discuss the benefits of a low-level palletizer. Let’s get started. The machines operate in an energy-saving method, with low noise and fulfil their task with excessive availability. An instance of this is the articulated-arm robot which impresses with its flexible adaptation to the circumstances within the palletizing of products in industry. When the robotic comes into contact with the packed goods, corresponding gripper units similar to a bag- or suction gripper guarantee mild handling. A decade later, within the Nineteen Eighties, articulated robot arms similar to those utilized in automotive manufacturing had been introduced in palletizing. They have the advantage of with the ability to handle packages or products individually, bringing greater flexibility to automated palletizing.

Benefits of a Low-Level Palletizer.

Here are some of the key benefits that you must know. Let’s follow them:

Reliability

The low-level palletizer system is designed to pull or pick the casually placed sags or stuff and load them according to the planned programmed by the operator. In simple words, it can provide the accuracy and management of the whole thing that you require in a managed work. It can give the accuracy and reliability of complete tasks without any disturbance.

Flexibility

Since makers are continually searching for more approaches to accomplish more with the less, versatile device also turns into a need. Automated low-level palletizers can deal with changes in bundle size and weight proficiently; perfect for uniquely blended bed loads. Moreover, the capacity to control the direction of specific things on the heap is essential for club-store show beds ("rack"). This is strategically significant for outward-confronting standardized identifications and marking just as following prerequisites for the pharmaceutical business.

Increased Productivity

Low-Level Palletizer can provide lift efficiency and uptime with fewer workforces. The fully Programmed palletizers are intended to convey a high pace, some up to 4 cycles for every moment. Additionally, the low support needs and operational straightforwardness give the organized work that put resources into a low-level palletizer, an exceptionally rapid rate of profitability (ROI). In short, it can help to complete the task in less time and also increase productivity.

Small Equipment Footprint

A little impression, structured by separating the infeed and bed dealing with frameworks from the primary edge, takes into consideration position in restricted floor spaces. Measured parts are equally considered fundamental redesigning with extra alternatives for future needs.

Efficiency

Low-level palletizers are legitimately connected with stacking and emptying of the things in the industry and working environment. There is no requirement for changing the levels while stacking. Along these lines, stacking time can be spared, and productive work is gotten. It’s not less than a capable machine.